Krakul teamed up with Evocon to design a smart IIoT (industrial internet of things) production monitoring device, capable of wirelessly gathering critical data to analyse the production processes.

“During the last six years, wireless communication has remarkably developed and stabilised, so we decided that it is time to find a solution, which could help our clients collect data faster and more conveniently than before. Our primary focus was on wireless connectivity and communication between different devices.

Krakul was the only company that took up the challenge. And thankfully, their team left a good impression. The fact that Krakul’s team had worked with wireless connectivity solutions for international companies was also reassuring.

We got a solution that was much easier to install compared to the older version. The new solution doesn’t require managing network cables, and for us, managing and setting up the new devices is much easier than before.

We recommend Krakul’s team to develop similar IIoT solutions.”

Evocon – OEE software to help monitor and simplify machine data

Evocon offers a visual and user-friendly OEE software that automates the data collection from manufacturing machines and provides real-time information about their performance. Trusted by manufacturers around the world, Evocon’s solutions are used in over 47 countries and 14 industries, ranging from wood and food to plastics and metal production.

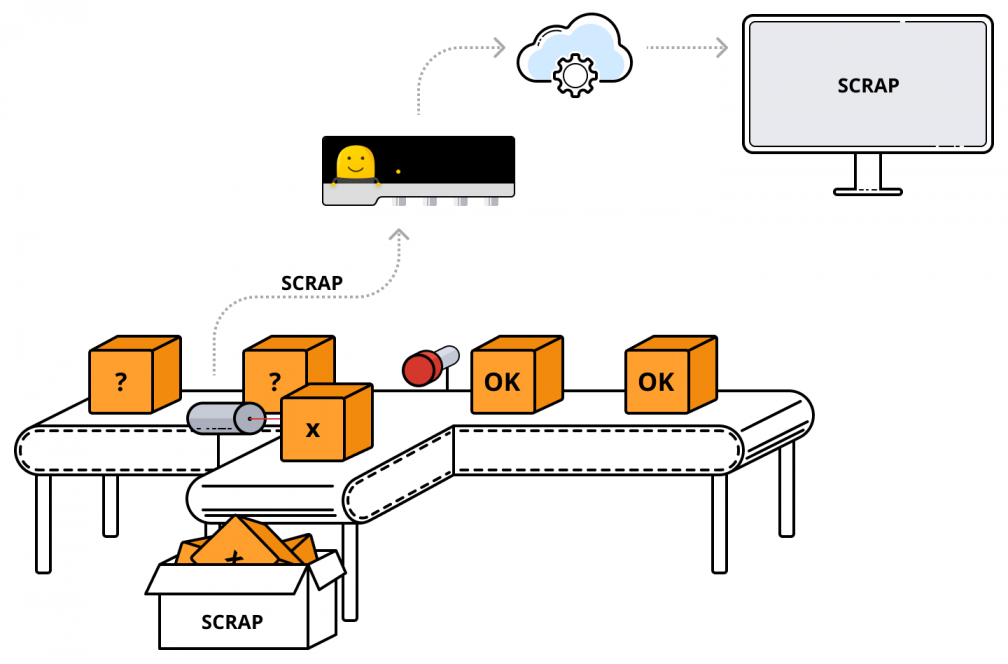

Gathering production data wirelessly

Evocon had previously built a production monitoring device with a former partner. The IIoT device worked but was somewhat clunky in terms of the user experience.

The other issue was that previously the deployment of the solution required extra cabling as connection via WiFi was not a reliable option at the time. However, with the new technological advancements, the situation had changed. Thus the solution was becoming outdated and needed an update to keep up with the times.

Evocon’s team knew that they needed to bring in a new IoT development partner.

A company who could design a next-generation device that would be wireless and have a better user experience whilst being easier to deploy, maintain and upgrade. Their previous experience led them to look for a business who could work as a long-term partner for maintenance, bug-fixing and extending the device capabilities.

Fortunately for us, they had heard positive feedback concerning Krakul and our previous developments with IoT devices, hence why they reached out to us.

Build a smart IIoT production monitoring device

The first step for us was to identify Evocon’s needs.

Their team approached us with an initial idea about what features the IIoT product needs. However, our prior experience highlighted that there is always a need for further in-depth analysis, before we can give time and price estimates, or even begin the actual engineering work. Similarly, we began by having numerous meetings, consultations and became familiar with the previous version of their device.

These discussions led to an understanding that their primary need was to integrate WiFi into the device to support wireless capabilities. The aim was to remove as many cables as possible and design the device to be more compact. Simultaneously, we were the IIoT product would be used in an extreme environment near factory production lines.

With our vision, the product should be designed to be more robust and capable of thriving in extreme high-voltage environments, supporting wireless connectivity. The PCB-s had to be engineered to withstand harsh and unpredictable environments, where voltages can rise upwards to 2000 volts since a faulty device could potentially have serious repercussions.

We began developing the hardware and software parallelly throughout the IIoT product development process. While the hardware team started figuring out the electronics and mechanics of the end product, the software team was hard at work.

The software development process broken down looked like the following:

1. Create epics in Jira to break down the development process and optimise the dedicated time. This involved a meeting with the firmware developers team where we discussed what the big main modules we need to develop are and what is the most logical order to implement them.

2. Next, we started developing three things in parallel:

- Get the new device’s digital GPIO reading system working with the same functionality that the previous device had

- Connect the device to WiFi

- Connect the device to the AWS MQTT server

3. After we had the server connection up and running, we started fine-tuning communication protocol specifics with Evocon. The main questions to solve were:

- What is the required data format?

- Where and when should the data be uploaded?

- What commands will the device receive from the server?

4. In the final step, we developed additional features that were not present in the previous device version, like the analogue to digital (ADC) and I2C sensors data acquisition. The main challenge was getting the ADC reading as precise as possible. This required long discussions between the hardware and firmware team on how exactly should the measuring hardware schematic look like and how should the ADC driver be used in firmware.

Meanwhile, our hardware team began working with integrating the mechanics of the previous version with the newer model, schematising new PCBs and figuring out the necessary isolation system for safety reasons.

One peculiar concern was the size. We had to change the mechanics of the product because the new features could not fit into the designed case, mainly because the previous version did not have a WIFI antenna.

In total, the development process took around 3-4 months.

After testing the first iteration, one of the main concerns was the temperature. Due to suboptimal temperature sensor placement, the power consumption of the system affected temperature readings of the sensor.

After three iterations, we reached a viable IIoT product for client testing. In the second iteration, we solved the temperature issue by moving the temperature sensor away from heat-generating components and made more minor adjustments. The third iteration was final, with a couple of minor modifications.

Evocon implemented five products for testing in a factory setting.

Our third iteration turned out to be great. The usual industry standard of a prototype being sent back to development in the industrial electronics sector is +/- 2 days. Our design worked as intended for about two weeks, which proved to be enough for broader implementation.

We supply the designed IIoT devices and work on next-generation features for Evocon to this day.

The unknown is uncertain, but problems are there for fixing

Before Evocon, Krakul had mostly thrived in an embedded world, dealing with low-voltage devices. Evocon was our first industrial-grade product that came with its fair share of learning.

A jump to withstanding 2 kV, while also having to figure out proper isolation, was a challenge we could not approach lightly.

There was little margin for error, a faulty device with a potential to explode could cause thousands of euros in damage to production machines. Worse, it could permanently injure someone’s face.

The whole development journey allowed us to introduce ourselves to the world of smart factories, industry 4.0 and IIoT devices. Moreover, it raised us out of our usual comfort zone and learned things outside of typical electronics design.

As the field was initially not wholly familiar to us, then we opted for following many of the proven approaches used by established R&D institutions. However, we did combine it with various conventional electronics building ideas.

The result was a great IIoT product that functioned just the way as intended, and the device is currently used in many production lines by Evocon’s clients.

Building Future IoT Solutions with Evocon

Today, we are continuing our cooperation with Evocon, still supplying our designed devices. We have already discussed developing the next generation of production monitoring solutions and other variants of its kind.

Having now extensively worked with IIoT devices, we are ready to take on new challenges in the field of the smart industry. When the next project comes around, we will get even a little more creative about possible solutions.